Product Name: Scotch Yoke Pneumatic Actuator

Power Source: Nitrogen Gas or Natural Gas

Output Torque: 830 Nm to 250,000 Nm (Meeting ISO Standard Requirements)

Spring Reset: 307 Nm to 71,753 Nm

Working Pressure: 3 Bar to 7 Bar

Ambient Temperature Range:

Standard: -20°C to 80°C

Low temperature: -40°C to 80°C

High temperature: -20°C to 120°C

Ingress Protection Level: IP65

Explosion-proof Level: Ex d IIC T6

Safety Integrity Level: Fulfilled SIL2(1001)/SIL3(1002)

Application: Used to Drive Ball Valves, Butterfly Valves, Plug Valves (Any 90 Degree Rotational Type Valve)

Features of Scotch Yoke Pneumatic Actuator

1. Piston Bar and Guiding Bar

The piston bar and guiding bar, featuring refined surface treatments, are paired with a self-lubricating bearing. This combination ensures exceptional resistance to wear, significantly prolonging the lifespan of all moving components.

2. Pneumatic Actuator Coatings

Constructed to endure harsh conditions, pneumatic actuators are fortified with multiple layers of protective coatings. The interior of the gas cylinder is lined with PTFE, boosting its ability to resist corrosion and enhancing its self-lubricating capabilities.

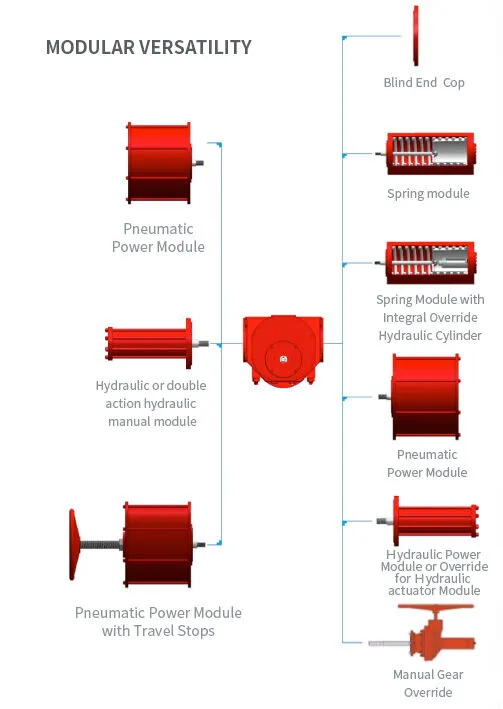

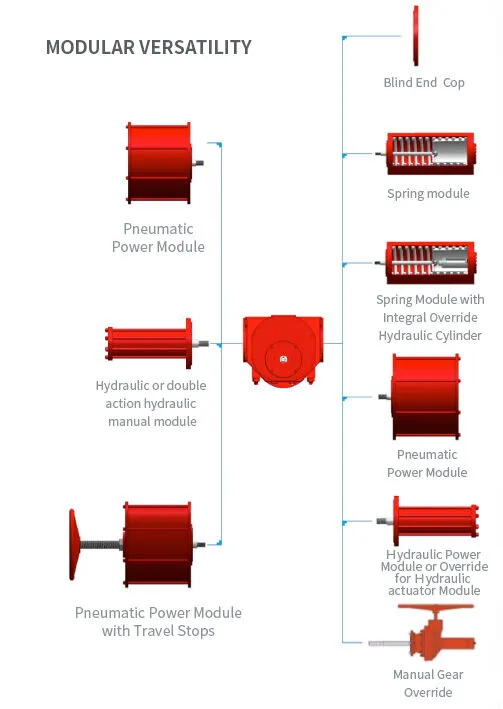

3. Pneumatic Actuator Components

The pneumatic actuator consists of a driving module, cylinder, spring, and optionally, side units. These components are engineered for straightforward installation, detachment, replacement, and secure fastening. They are available for purchase individually, allowing for a streamlined spare-parts inventory.

4. Safety in Spring Module Operation

To safeguard operators during the assembly and maintenance of the spring module, it is designed to be removed as a single unit from the actuator along the axis of the cylinder module. This design prevents accidental damage from spring force to personnel or the actuator itself.